Structural redesign for an evolving art form

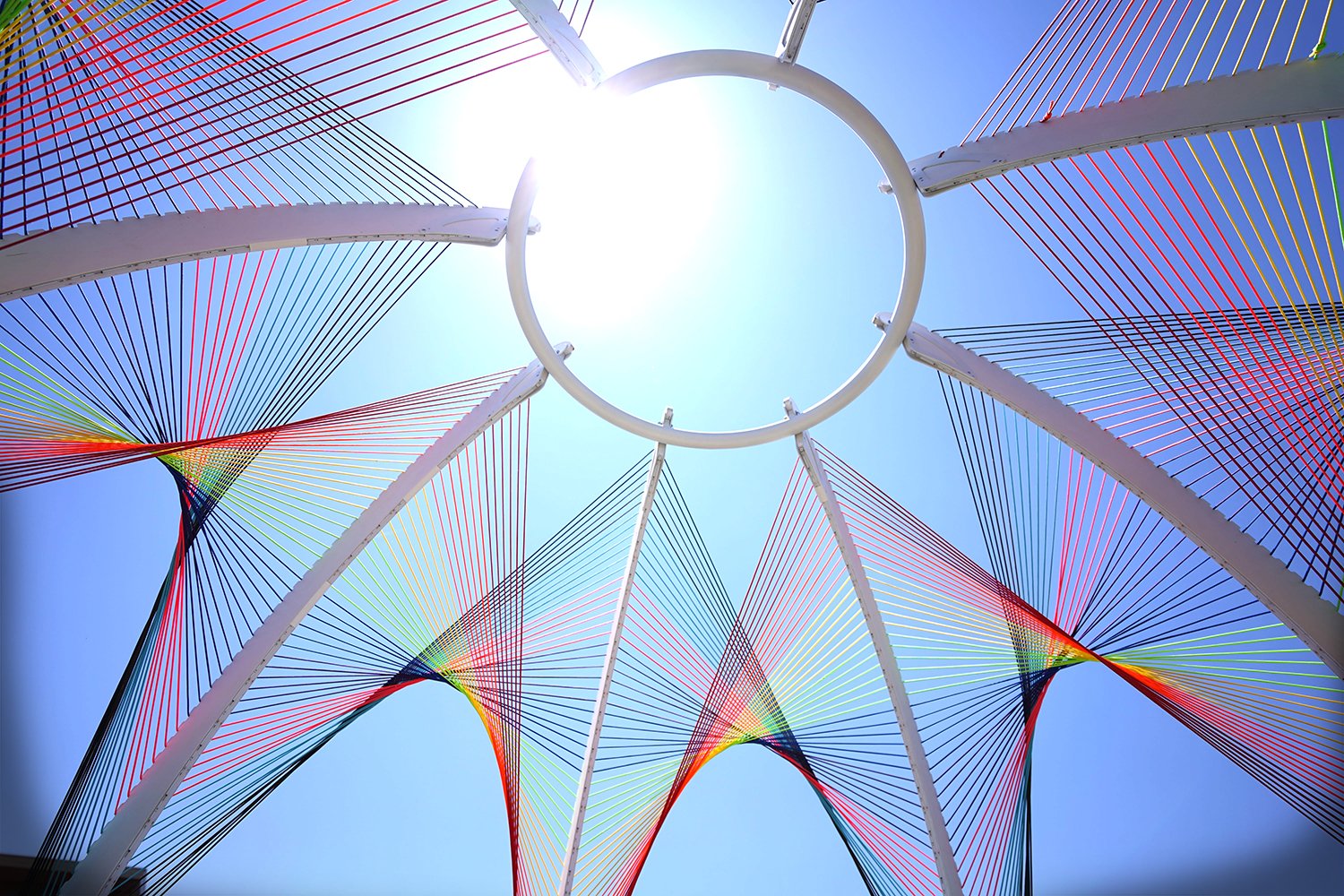

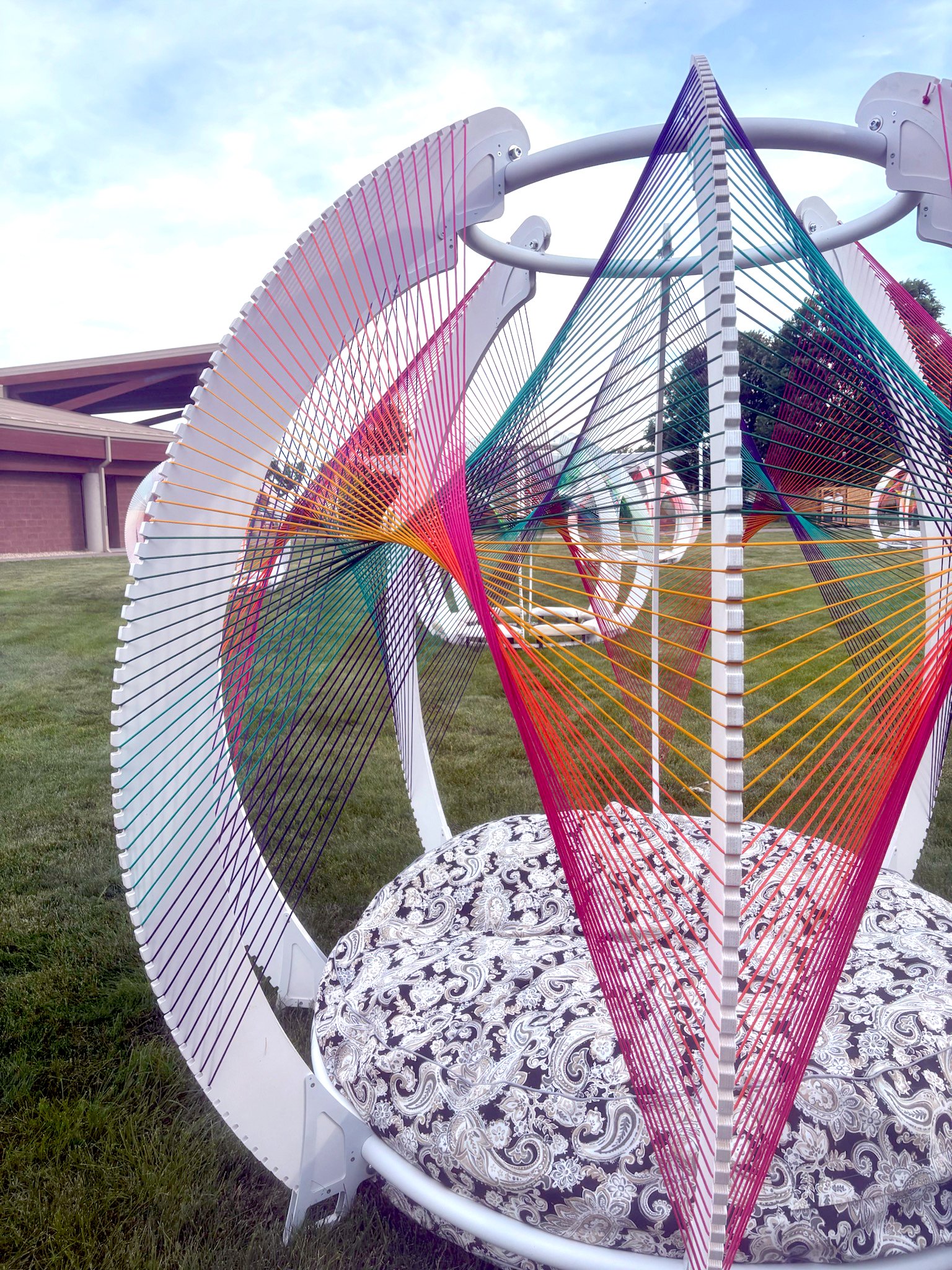

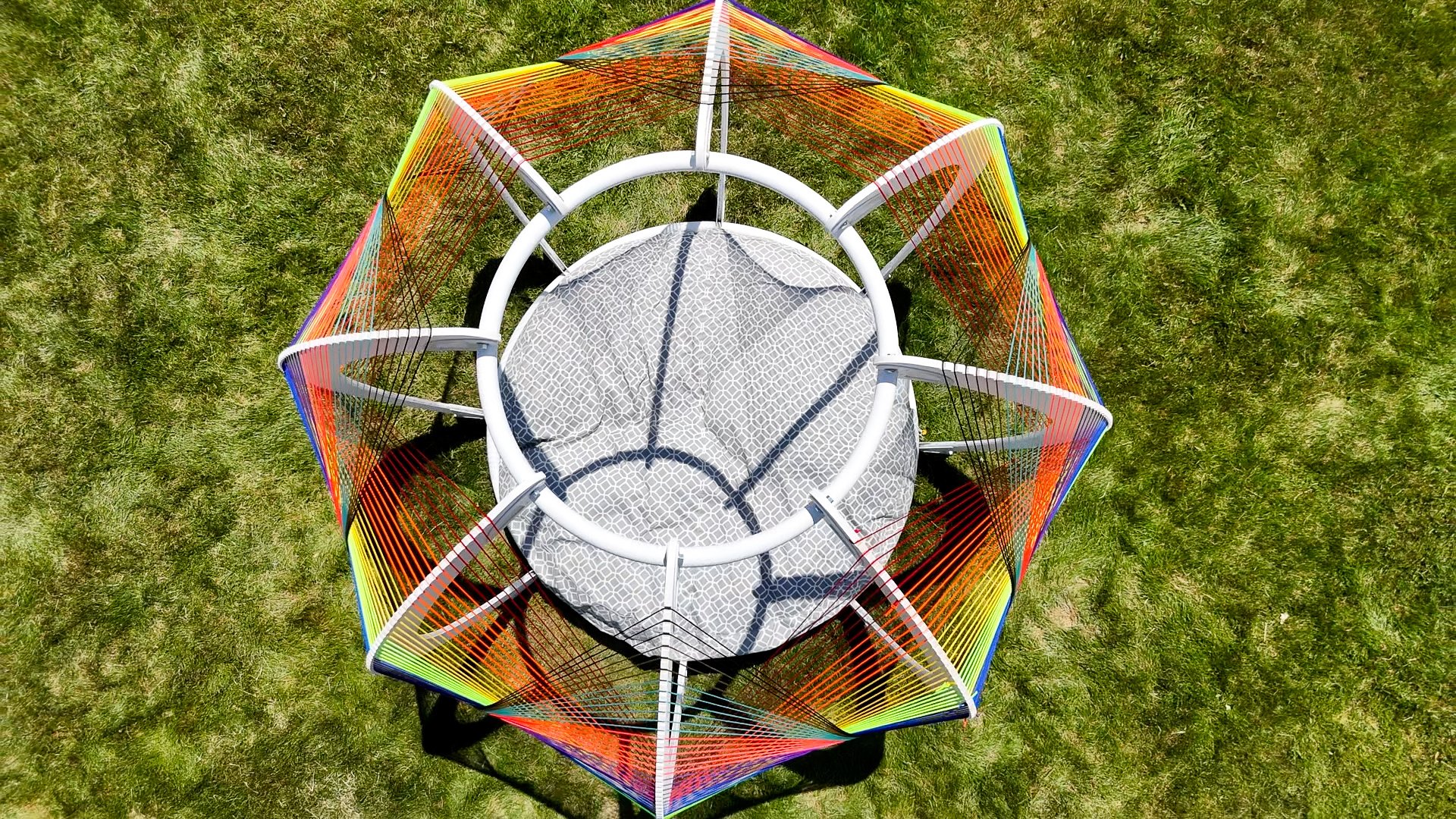

Lyre 72 is a large-scale woven light sculpture series by artist Diana Merkel, featuring colorful, handwoven thread patterns stretched across a towering spherical frame. These orbs serve not only as striking visual centerpieces, but also interactive seating areas designed for public spaces and high traffic events.

I partnered with Diana to redesign the frame structure of Lyre 72 with the goal of making installation faster, easier, and more robust against a range of demanding environments—from snowy ski resorts to the dusty plains of the Black Rock Desert. My role was to engineer an optimized V2 frame: one that assembles in a fraction of the time, travels easily, and holds up under real-world stress.

Lyre72 V1 Installation at the 2024 Aurora Borealis Festival, Aurora CO

Lessons from the Road

The original Lyre 72 frame (V1) was built from CNC-cut plywood ribs and lap-jointed hub plates. It is functional, clean, and has a solid presence—but like many first-generation designs, it revealed opportunities for improvement over time.

As the demand and scale of installations increased, so did the pain points:

Long Setup Time: Each orb frame required two people and ~45 minutes to assemble.

Environmental Sensitivity: Wood-on-wood lap joints swelled or loosened with changes in humidity, temperature, and wear.

High Fastener Count: Required up to 48 fasteners, multiple tools, and sometimes a little brute force

Delicate Electronics: Left delicate LED strips and connectors vulnerable during transport and setup

These are natural challenges that come with building a complex, modular piece that needs to perform in wildly different environmental conditions.

V2 was our opportunity to build on that foundation and refine it for the road ahead.

Lyre72 V2 Installation at the 2025 Adams County Pride Festival, Brighton CO

A Frame Built for Speed

For V2, the goal was simple: eliminate every source of friction during setup and strike. That level of optimization goes beyond structure—it means rethinking every tool, process, and potential failure mode from the ground up. Key areas of focus were:

Interface Optimization: The V2 frame slips together in under 15 minutes with just two tools. That’s a 67% reduction in frame assembly time!

Hardware Reduction: Just 16 matching fasteners—all ½″ bolts with a coarse thread pitch for fast hand-threading. They're easy to grip, easy to spot if dropped, and quick to tighten with just a couple turns of a wrench. This 67% reduction in fasteners saves time and money.

Hardware Management: In V1, hardware lived in multiple boxes—tiny parts, lots of spares, and a setup process that often started with a scavenger hunt.

V2 uses a custom hardware organizer with dedicated slots for each fastener. A quick glance at the lid tells you if anything’s missing—no digging, no guessing, no need to open the box.Steel Ring Structure: The plywood hubs and angle brackets were replaced with robust custom-fabricated steel rings. Welded rib mounts lock each rib in place with just two bolts—no mallets, no guesswork.

Safe and Reliable Connections: Each rib terminates in decorative steel plates that create strong, repeatable metal-to-metal interfaces. The joints are designed for flexibility during assembly and lock solidly in place, with built-in features to prevent tipping or misalignment.

Balance is Key: Each rib’s foot is positioned based on its center of mass, so it nearly stands upright on its own. This even balance makes alignment a breeze!

LED Improvements: LED strips run along the inside edge of every rib. In V2, they’re prepped with better adhesives, shielded by the steel plates at each end, and stowed in custom notches to keep connectors protected during transport—no more crushed plugs or tangled wires.

Thinking Ahead: V2 includes built-in pass-through holes and contingency features that make field repairs quick and straightforward. If a screw hole strips, you can resolve it on-site without drilling new holes or fabricating replacement parts—because the show must go on!

This level of design-for-assembly makes it possible to deploy multiple orbs quickly and consistently, with a lighter tool kit and a whole lot less stress.