Amazon Go

Hardware R&D

Advanced Development

Robotics and Automation

Role: Mechanical Engineer - Weight Sensing Systems

Years: 2017–2019

Location: Amazon HQ - Seattle Washington

At Amazon Go, I was part of the core hardware team behind “Just Walk Out” (JWO) the world’s first checkout-free retail experience. My primary focus: inventing intelligent, tech-enabled merchandising systems that detect customer-product interactions with high confidence and mechanical robustness to survive in demanding retail environments.

Please note that due to NDAs the information I can share here is very high-level and limited.

What I did:

Improved our core weight-sensing technology.

One of my earliest projects involved looking at two smart shelving systems nearing launch but still plagued by stability issues. Existing data tools were slow and unreliable, so I built a streamlined data collection and visualization suite that revealed real-time system behavior in a way we had never seen it before. Within days, we uncovered key issues—temperature drift, environmental vibration—and implemented fixes that helped push those systems across the finish line.

Raised the bar.

What began as a support role quickly evolved. By demonstrating a strong technical foundation, a deep understanding of our sensing systems, and a relentless bias for action, I earned a reputation as someone who could really move the needle. I leveraged a strong background in rapid prototyping methods—mechanical, electrical, and software—to prove out ideas quickly and clearly. That execution shifted expectations and landed me a second role as the head of our labs and maker spaces. I went from debugging late-stage systems to owning the labs and early R&D of entirely new merchandising concepts in under a year.

Led advanced R&D to explore new merchandising capabilities.

I conceived, prototyped, and validated early shelving technologies that enabled new product formats—peg hooks, magazine racks, bulk bins, drink dispensers, and more. My role was to prove feasibility fast, de-risk technical unknowns, and pave the way for production-ready systems.

Acted as an internal R&D consultant for high-ambiguity programs.

I was pulled into early-stage projects where creativity was critical and speed was everything. My ability to operate across disciplines made me the go-to engineer for first-pass concept development and validation.

Built automation and tooling that changed how we tested.

I developed internal platforms—both hardware and software—that dramatically accelerated our ability to test and validate ideas:

Custom test robots that automated multi-day experiments, generating cleaner, higher-volume data than manual testing ever could.

Data collection, calibration, visualization, and reporting tools were used across engineering and research teams.

Signal processing and diagnostic pipelines leveraged by scientists, engineers, and field technicians.

Hooks in the wild! Spotted at Amazon Fresh in London England.

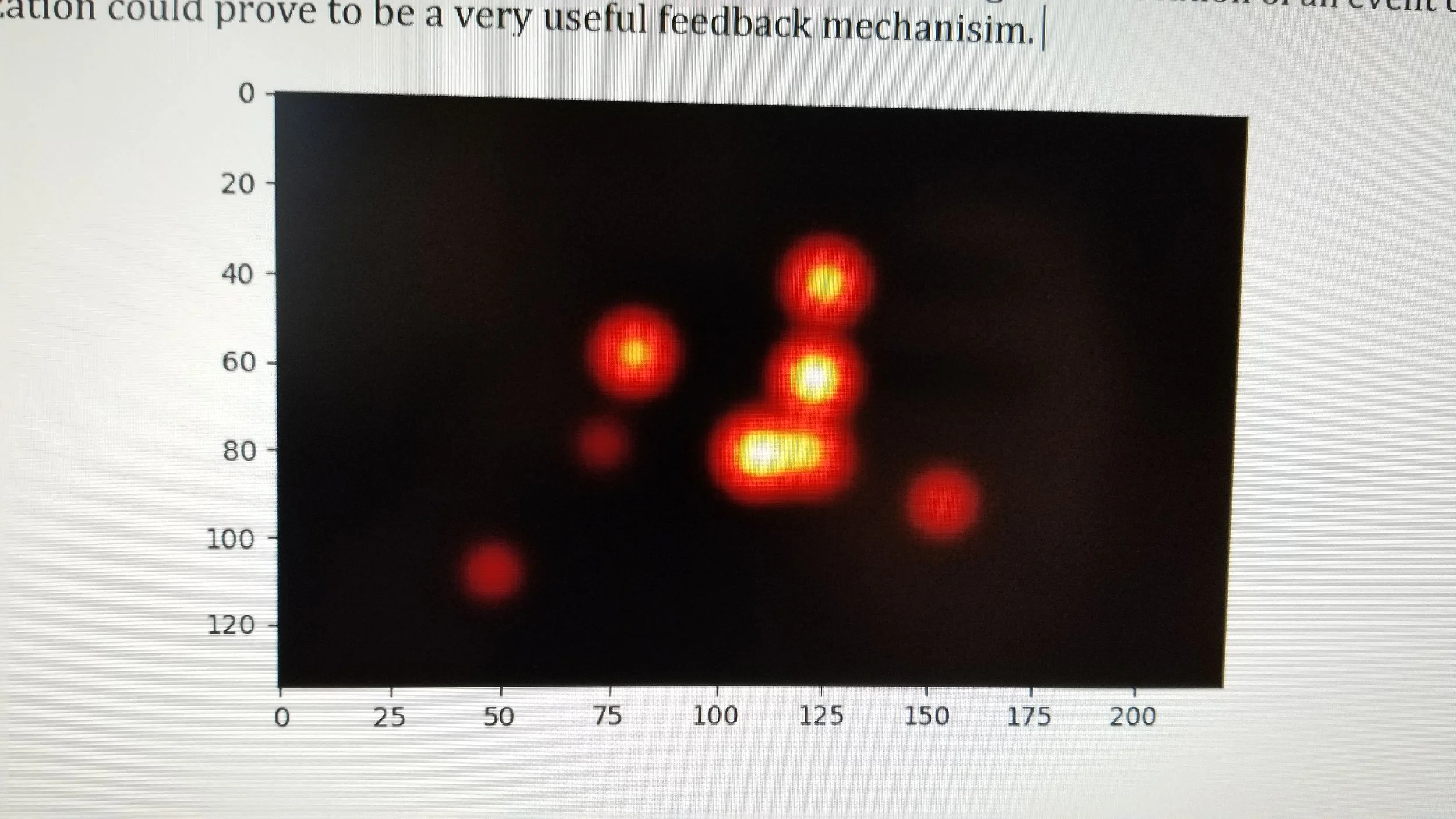

Heat Map - An early data visualization I created that shows localized weight changes on the surface of a shelf.

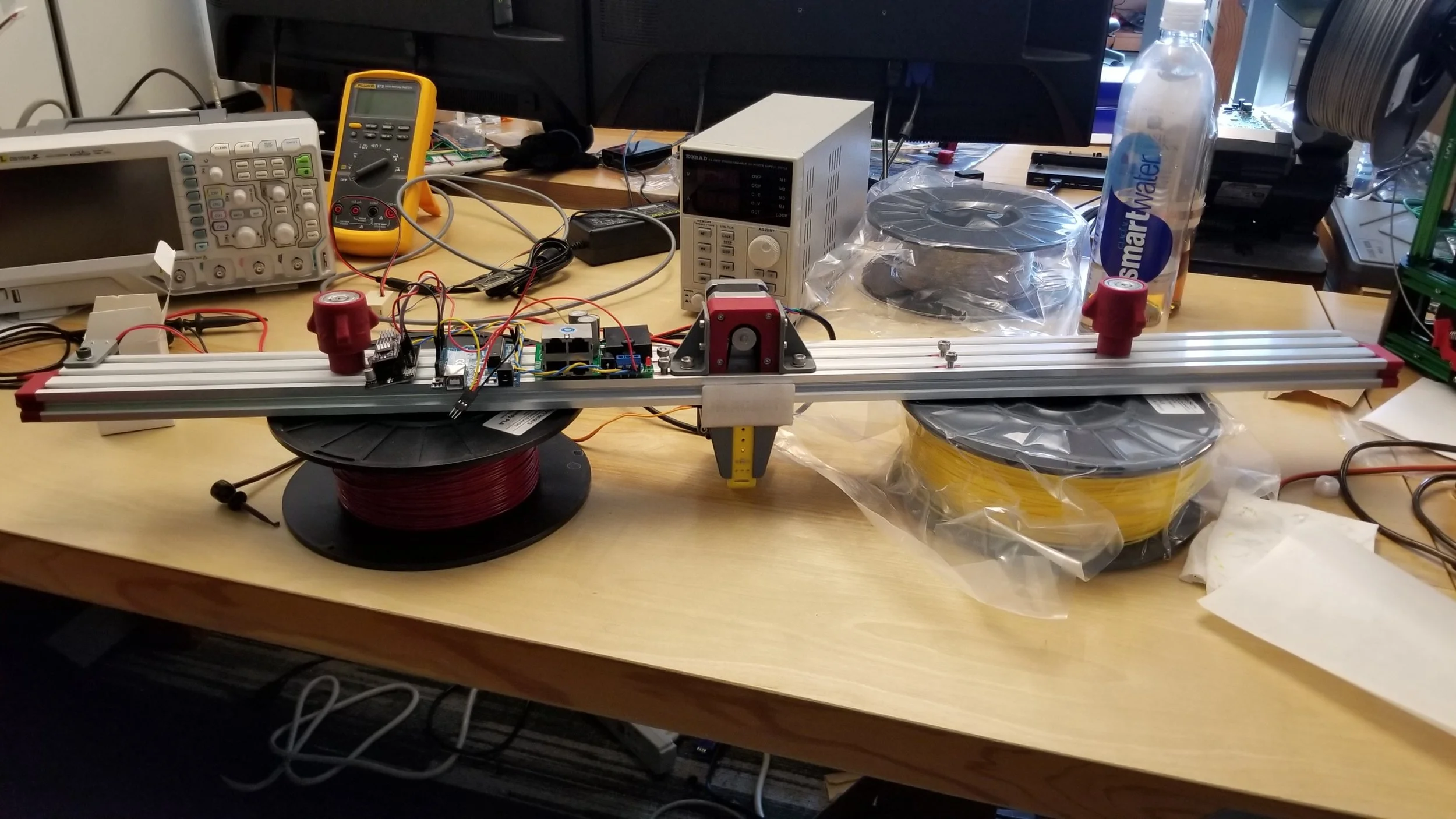

Dr.Roboto - One of my first automated shelf testing robots.

How I did it:

I work the full stack.

With a foundation spanning mechanical, electrical, and software engineering, I see the big picture in high resolution. That perspective helps me bridge communication gaps—and build entire systems independently. From R&D through integration, I can design the hardware, write the code, and build the tools to test, validate, and evolve the work.

I move early and make it real.

I specialize in first-pass prototypes—turning blue-sky conversations into working proofs at breakneck speed. I help teams cut through ambiguity and make confident decisions before allocating further R&D resources.

I lift the culture by example.

Innovation isn’t just output—it’s behavior. I welcome scrutiny, offer clear feedback, and work in the open. By building fast, thinking aloud, and turning obstacles into opportunities, I help normalize a culture of enthusiastic curiosity, trust, and continuous improvement.

I earn trust by delivering.

I wasn’t anchored to one team—I was the person leadership called when traction mattered. That trust came from consistent, visible impact: tools that scaled, tests that saved weeks, and systems that just plain worked.